Hon Hai Technology Group (Foxconn) unveiled its exceptional, practical and cutting-edge electric cargo van on Wednesday, part of an unprecedented line-up of technologies showcasing the contract design and manufacturing service (CDMS) of the world’s largest technology manufacturer and service provider.

At the same time, Foxconn signaled mass production plans for a sporty and intelligent crossover, the MODEL B; provided an update on the commercial production of its first family SUV, the MODEL C; and disclosed the imminent launch of its first self-developed prototype low-Earth-orbit satellite.

At its 4th annual Hon Hai Tech Day (HHTD23), Foxconn Chairman and CEO Young Liu said, “With the new MODEL N electric cargo van, we demonstrate a full range of vertically integrated capabilities. Traditional automotive companies can tap into all of these. In three short years, Foxconn has displayed a remarkable range of high-end sedan, passenger crossover, SUV, compact pick-up, commercial bus and commercial van.”

According to Foxconn Chief Strategy Officer for EVs, Jun Seki, Foxconn currently has about 14 potential customers it is in touch with and 23 development projects are being carried out. He reinforced the idea of accelerated development for EVs based on modular components in the supply chain and a platform-based development strategy. India and Japan should be the next great potential for EV development.

A vertically integrated supply chain, but particularly in the semiconductor segment, underpins Foxconn’s resilience in its EV efforts, said Foxconn Chief Strategy Officer Shang-yi Chiang. Moreover, the “System Foundry Business Model”, which can meet the diverse semiconductor demand of the IoT market, will be able to effectively save manpower, reduce capital investment, and shorten chip time to market.

Both CSOs took to the stage for the first time at Foxconn’s flagship event adding to substantive insights on electromobility. HHTD23 was the biggest one to date with more than 1,000 attendees. Two of Foxconn’s global partners also shared the stage for the first time: US chipmaker NVIDIA and German automotive supplier ZF Group. Each brought fresh perspectives in the areas of AI and new generation mobility.

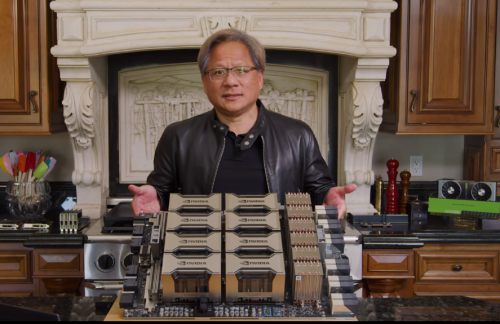

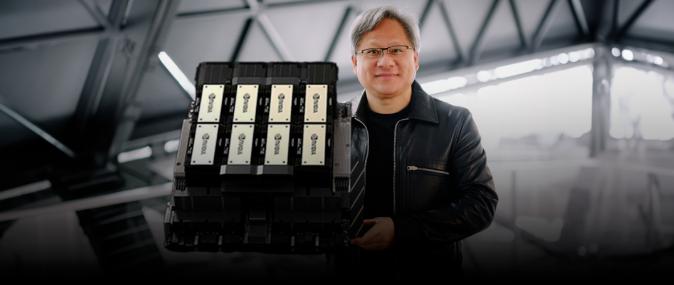

NVIDIA Founder and CEO Jensen Huang, who appeared on stage with Chairman Liu in a MODEL B, said, “A new type of manufacturing has emerged – the production of intelligence, and the data centres that produce them are AI factories. Foxconn, the world’s largest manufacturer, has the expertise and scale to build AI factories globally. We are delighted to expand our decade long partnership with Foxconn to accelerate the AI industrial revolution.”

Foxconn Smart EV will be built on NVIDIA DRIVE Hyperion 9, NVIDIA’s next-gen platform for autonomous automotive fleets, powered by NVIDIA DRIVE Thor, its future automotive SoC. Foxconn Smart Manufacturing robotic systems will be built on NVIDIA Isaac AMR autonomous mobile robot platform. Foxconn Smart City will incorporate NVIDIA Metropolis intelligent video analytics platform.

E-mobility and advanced chassis solutions are the core technologies of German automotive supplier giant ZF Group. “The electric vehicle business is growing rapidly in the Asia-Pacific and global markets with a promising future. ZF is at the forefront of e-mobility innovations with class-leading solutions and partnerships,” said ZF Group CEO Holger Klein, who was in Taipei for HHTD23, his first visit since Foxconn and ZF announced a 50-50 partnership in July.

“In the future, the two companies will make full use of each other’s capabilities to expand their product range in both internal combustion engine (ICE) and electric vehicles. ZF Group has been operating in Taiwan since 1988, and our business partnership with Hon Hai will further strengthen our presence in the Asia-Pacific region and globally as we move towards Next Generation Mobility.”

The MODEL N complements Foxconn’s remarkable stable of electric vehicles solutions, providing more choices for automakers preparing to enter the electric era. MODEL N subverts the image of traditional vans with innovative thinking, combines the concept of sustainable environmental protection promoted by the new energy generation, and has more humanised and considerate designs.

Its clean lines and roomy build support safety first with a “tap and unload” one-button design that activates automatic flipping cargo compartment boarding steps, safety warning projection lights on both sides and rear, and the opening of the electric rear rolling door. The overall design makes the driver safer and more comfortable when transporting cargo. Its efficiency is expected to bring a new transportation experience to logistics operators.

The MODEL B, following its unveiling last year, has been well received. The design of the mass-produced version retains the most popular technological simplicity and aerodynamic styling. It adopts a new generation of centralised EEA architecture, which will be able to support more functional smart cockpits or intelligent control driving modes.

It can also be equipped with 15.6-inch IVI (in-vehicle infotainment), electronic digital rearview mirrors, and Matrix LED smart headlights and UWB (ultra-wideband communication technology) digital keys. Automakers and customers can choose and match according to market demand.

The MODEL C has completed a number of verifications, such as: durability test, water immersion test, climbing/high-speed performance test, and has also completed winter/summer experiments in the United States. In addition, Foxconn will also provide performance and extended range versions of the MODEL C, giving brand customers a selection to choose from based on power, endurance and speed.

The first passenger electric SUV made under Foxconn’s CDMS business model received an official license plate in Taiwan, a recent milestone, showing it meets the four major categories of safety, pollution, noise, and energy consumption tests specified by the competent authority, and can be officially put on the road. The MODEL C has been adopted by a brand customer in Taiwan and officially launched for sale. Hon Hai will mass-produce and deliver the vehicles in November. Consumers will be able to drive them on the road in the first quarter of next year.

【2023年10月18日】富士康科技集团今日举办“2023鸿海科技日(HHTD23)”,正式发表的MODEL N电动物流车以及MODEL B量产版跨界休旅,展现集团打造不同级距电动车的实力。今年HHTD23按往例由刘扬伟董事长亲自主持,除了推出新的电动车解决方案,揭露富士康打造的低轨道宽带通讯卫星外,更邀请NVIDIA创办人暨执行长黄仁勋(Jensen)与ZF执行长Holger Klein博士登台。富士康蒋尚义半导体策略长以及关润(Jun Seki)电动车策略长也首次同时现身,与外界分享富士康在半导体以及电动车领域的发展方向与最新进展。

连续第四年举办的“鸿海科技日”,今年HHTD23一口气将过去三年来,集团推出的电动车解决方案同台展出,同时扩大展区规模,展现富士康在智慧制造、智慧电动车、智慧城市的三大平台解决方案整合实力。台北南港展览馆2馆四楼与七楼展区,相关产品内容是去年的三倍、展位面积多出50%,吸引超过1000名海内外贵宾到场。

力推CDMS商业模式 服务跨入电动世代的传统车厂

“现在富士康正在从一家制造服务公司转型为平台解决方案供应商!”富士康董事长刘扬伟在活动开场,特别向准备跨入电动车领域的传统车厂喊话,“富士康的CDMS(委托设计制造服务)商业模式为汽车产业提供完整且能客制化的解决方案。这种商业模式能大幅减少投入的成本,并且缩短上市时间,而这两点正是决定未来电动车成功的关键要素。”

刘扬伟董事长与NVIDIA创办人暨执行长黄仁勋透露,两家公司将合作开发下世代人工智能与机器人生产系统,加速全球工业数字化的进展,同时在富士康推出的智慧电动车、智慧制造、智慧城市等三大平台领域探索运用NVIDIA系统,持续优化智慧未来的可能性。

NVIDIA创办人暨执行长黄仁勋表示:“制造智慧这种全新的制造业已经崛起,而生产这些智慧的资料中心就是人工智能工厂。作为全球最大的制造商,富士康具有在全球建立AI工厂的专业知识和规模。我们很高兴扩展与富士康的长达十年的合作,以加速人工智能工业革命。”

富士康双策略长 首次公开阐述集团最新半导体及电动车策略

去年11月正式加入富士康的蒋尚义策略长,在上午场的论坛中,首次登上HHTD舞台对外分享富士康半导体领域的电动车发展方向。蒋策略长认为积体芯片(integrated chiplets)将是后摩尔时代的主要科技潮流之一。随着IOT时代的来临趋势下,芯片功能将越来越多元,在这个情形下,积体芯片次系统封装将会成为主流。蒋策略长提出“System Foundry Business Model”,通过此商业模式将能有效节省人力、减少资本投资、缩短芯片上市时间。

ZF Chassis富士康切入电动车市场的关键布局

紧接着,今年2月加入富士康,拥有37年车界经验的关润策略长登场提到,价格昂贵、充电困扰、无法获利这三个痛点,让电动车成为传统车厂很沈重的负担!他认为,“透过富士康的CDMS商业模式,有效运用供应链中模块化的零组件,辅以平台化的开发策略,将能加速电动车的开发时程!”关润进一步透露,“目前富士康已有14个正在接触的潜在客户,累计有23个开发项目正在执行中!”他进一步从产业、法规面分析,特别看好印度以及日本将会是下一个深具电动车发展潜力的市场。

HHTD23上午场节目中,特别安排关润策略长与ZF执行长Holger Klein博士对谈,畅谈双方对于电动车未来的看法,也分享了ZF Chassis合资公司对富士康与ZF双方的重要性。ZF集团董事Stephan von Schuckmann也应邀参加了鸿海科技日。

ZF执行长Holger Klein博士表示,“亚太和全球市场的电动车业务发展快速,前景乐观。ZF凭借领先的解决方案和合作伙伴关系,走在电动车业产创新的前端。今后,和富士康双方将充分发挥彼此的能力,扩大在燃油车和电动车领域的产品范围。早在1988年,ZF集团就开始在台湾开展业务,我们与富士康的业务合作将进一步加强我们在亚太区和全球的实力,在向“下一代出行”迈进的进程中,提升双方的影响力。”

MODEL N电动物流车登场 提供运输业者更永续环保的选择

今年鸿海科技日,再推出MODEL N电动物流车,补足各种不同级距的电动车解决方案,提供给准备跨入电动世代的车厂更多选择。MODEL N以创新思维颠覆传统货车形象,结合新能源世代提倡永续环保的理念,更多人性化贴心设计。在外型方面,子弹式车头设计,贯穿式线条,自动翻转货舱登车踏板,两侧及后方安全警示投射灯,一键开启电动后卷门,让驾驶在运送货物时,能够更安全、更舒适、更有效率,可望带给物流业者全新的运输体验。

此外,去年首度亮相即大获好评的MODEL B智能跑格Crossover,一年多来收到各界好评不断,在量产版设计上,保留最受欢迎的科技简约、空气力学造型设计,包括S-DUCT导流设计、Air Curtain D柱气帘等,但在车长、车宽略为调整。MODEL B科技含量方面,采用新一代中央集中式EEA架构,将能支援更多功能的智能座舱-智控驾驶模式,亦可搭载15.6吋IVI车用信息娱乐、电子数位后照镜、Matrix LED智慧头灯 – UWB(超宽带通讯技术)数位钥匙等,未来车厂客户可因应市场需求选择搭配。

今年科技日上,多台MODEL C登场阵容吸睛,目前MODEL C已完成多项测试验证,如:耐久测试、泡水测试、爬坡/高速性能测试,也已于美国完成冬/夏季实验。此外,富士康科技集团未来也会提供MODEL C性能版与续航版的衍伸车,搭载更强的动力、更快的0到100km加速表现及更长的续航力,让品牌客户选择。

近期相当热门的MODEL C,在台湾地区已取得正式车牌,意味这此电动SUV已满足主管机关规范的安全、污染、噪音、耗能四大类检测,可正式上路及提供予客户销售。目前在台湾地区已有品牌客户采用,并正式开卖,富士康将在11月陆续量产交车,预计明年第一季消费者就能开上路!

2050年净零碳排 富士康要求万家供应链伙伴一起推永续

鸿海科技日除了展现创新实力,也不忘净零减碳爱护地球,会场接驳由富士康打造的MODEL T电动公交车担纲,落实永续生态圈-零碳交通。科技日会场,从灯光到空调所产生的碳排放,未来也将藉由富士康与海洋大学合作项目,通过复育海藻创造出的海洋碳汇进行抵销,更会争取自愿减量的国际认证。

富士康已承诺在2050年做到净零碳排!今年4月,富士康的2030年减碳目标正式通过了SBTi的认证。富士康在遵守客户最高要求的同时,也订定了富士康最新的行为准则以及责任标准,并要求1万家供应链伙伴一起提高标准。富士康帮助供应商取得零废弃物填埋认证,要求供应商承诺使用100% 再生能源为富士康生产产品,并协助123家供应商进行碳盘查,进一步落实公司永续发展目标。

第一届的科技日,富士康发表 MIH 开放平台,透过发展标准化、模块化、平台化技术改变传统的汽车产业体系。第二届科技日,富士康推出了三款电动车,MODEL C、MODEL E、和MODEL T,以多元的电动车产品线,展现富士康在电动车研发生产的速度。第三届鸿海科技日,富士康不仅扩大推出MODEL B和MODEL V等新电动车款,更重新定义车用领域的CDMS。第四届的鸿海科技日HHTD23,首次邀请重要合作伙伴上台,富士康两位策略长各自分享富士康在电动车以及半导体端的发展策略。同时今年透过智慧制造、智慧城市、智慧电动车的三大主题,扩大关键零组件、软硬件的展示内容。让外界清楚富士康转型成为平台解决方案供应商的决心。